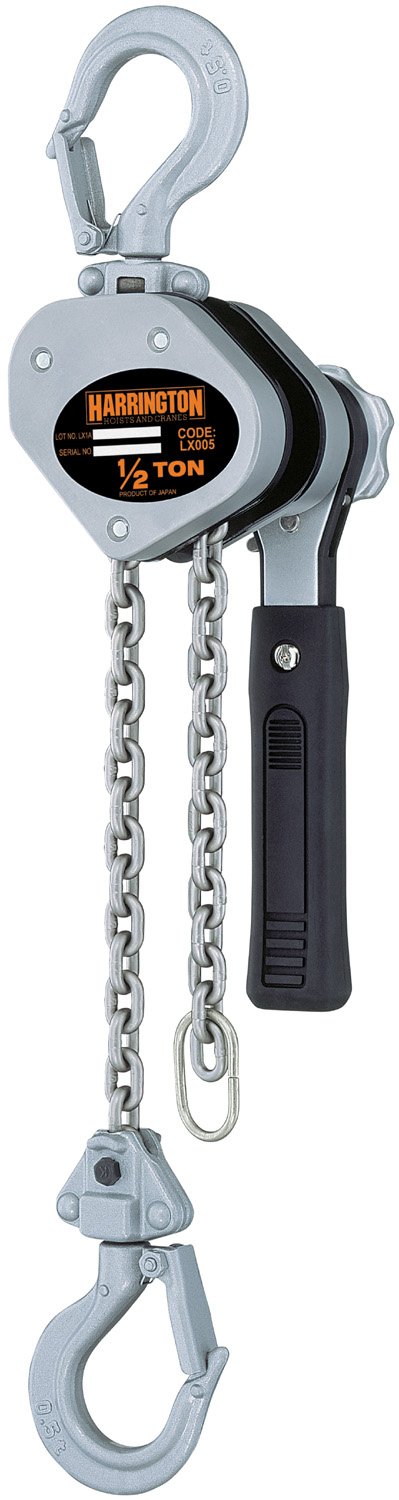

Description

The Lever Chain Hoist can lift a half-ton load by merely operating a lever by hand. Workers with back impairments or arm amputation can lift heavy loads safely. There are many uses for this hoist when electricity is not available for a powered lift. It can also be used with a gantry crane and trolley to lift and move heavy loads around a workshop. The lever action gives precise control as raising or lowering heavy loads.

Workers with common conditions such as these would benefit from a Lever Chain Hoist.

Arm Amputation, Back Injury, Back Pain, Fused Vertebrae, Herniated Disc, Multiple Sclerosis (MS), Quadriplegia, Scoliosis, Kyphosis, Lordosis, Slipped Disc, Spinal Cord Injury, Stroke, Traumatic Brain Injury (TBI)

Works great for:

Farmers

Tensioning fence wire

Lifting and lowering duals

Lifting livestock with leg injuries

Mechanics

Pulling and installing engines

Lifting and repairing heavy beams

Construction, Welders & Fabricators

Positioning heavy metal parts for fabrication

Lift and support heavy beams until secured in place

…and more.